服务热线

0512-57440069

Get SMS verification code

Search by part number

Product Type

Search By Size

Exact Search

Range Search

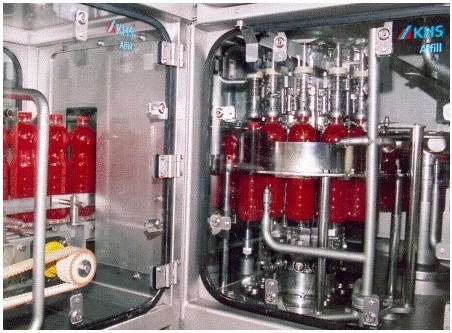

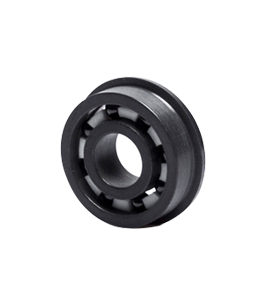

Ceramic bearings for food machinery

In some food filling equipment, bearings are particularly vulnerable to corrosion and damage due to working conditions. In some cold aseptic filling industries, bearings are required to be resistant to corrosive environments and not lubricated with any grease.

Ceramic bearings can meet these requirements, ceramic material characteristics can resist strong corrosion. For lubrication, ceramic bearings can operate quietly and normally without any grease. Sometimes there will be detergent and water contact with the bearings, and ceramic bearings are completely resistant to these fluids.

Ceramic bearings for corrosion resistant environments

Ceramics are more resistant to corrosion than most metals and alloy steels. Ceramic materials are more chemically stable and have lower chemical solubility. This makes ceramics better than metal materials in harsh environments.

Corrosion resistance characteristics are necessary in many applications and environments. Having to come into contact with certain chemicals in some harsh production environments, even water can sometimes cause corrosion of product components. A corrosion-resistant component can be a significant benefit to both production efficiency and cost effectiveness.

Ceramic bearings for vacuum environments

Due to the self-lubricating oil-free nature of ceramic materials, ceramic bearings can be used in ultra-high vacuum environments, solving the lubricating oil problem that ordinary bearings can never overcome.

Application Field:

Vacuum technology, such as scanning electron microscopy, turbo molecular pumps

Aviation - Spacecraft applications

Semiconductor production

Medical applications, such as X-ray tubes

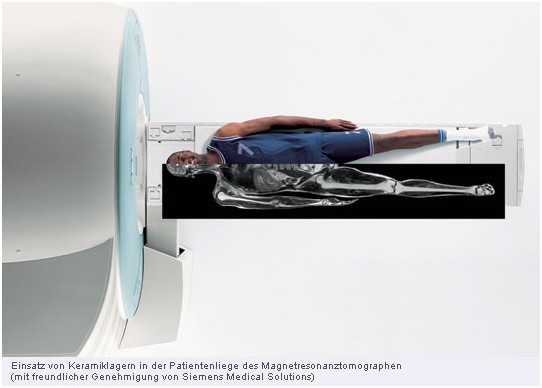

Ceramic bearings for completely non-magnetic environments

Magnetic resonance imaging (MRI) has become an indispensable part of clinical diagnosis and research in current medicine. NMR works by requiring a completely non-magnetic environment. Ceramic bearings can fully meet such requirements, not only completely no magnetic bearing, the performance of the bearings themselves is also very good, and the bearings can be used normally without any grease lubrication, but also more to ensure the sterile environment in the ward.

Miniature Bearing

Metric series d 1 ~ 4mm

Metric series d 5 ~ 9mm

Metric flange bearing d 1 ~ 4mm

Metric flange bearing d 5 ~ 9mm

Inch flange bearing d 1.016 ~ 9.525

Inch flange bearing d1.191 ~ 9.525mm

Deep Groove Ball Bearing

single row d 10 ~ 22mm

single row d 25 ~ 45mm

single row d 50~75mm

single row d 80-105mm

single row d 110~160mm

single row d 170~240mm

single row d 260 ~ 360mm

single row d 380 ~ 600mm

single row d 630 ~ 800mm

Full ball bearing d 25~100mm

Magneto ball bearings d 4~20mm

Ceramic Bearing

Zirconia ceramic ball bearing

Silicon nitride ceramic ball bearing

Ceramic bearing

Ceramic parts

Dental Drill Bearing

Dental Drill Bearing

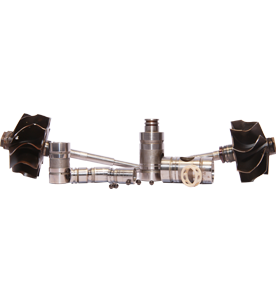

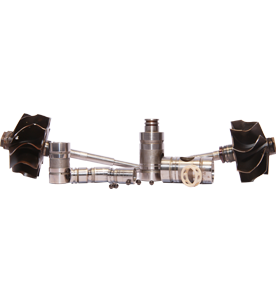

Turbocharger Bearing

Turbocharger Bearing

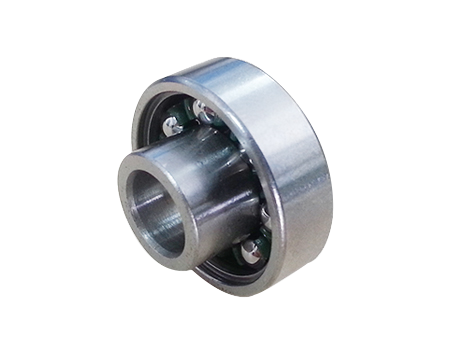

Stainless Steel Bearing

Stainless steel deep groove ball bearing

Flanged stainless steel bearing

Thin Wall Bearing

Open type

2RS type

Thin Wall Bearing

Angular Contact Ball Bearing

Single row angular contact ball bearing

Thrust Ball Bearing

One way thrust ball bearing

One way thrust ball bearing-aligning seat rings

Double way thrust ball bearing-aligning seat rings

Linear Bearing

LM…LUU

LM…UU/UUAJ/UUOP

LME…LUU

LM…UU/UUAJ/UUOP

KH...PP

Non-Standard Bearing

Full Complement Bearing

UV Groove Series

Arc,WV Groove Series

Bearing with Longer Inner Ring

Bearing with Coating

Bearing with Plastic coating